Fire Resistant Paint ADINA

Fire Resistant Paint ADINA is a highly viscous paste. After application and drying process it will create gray-white, continuous, smooth and matt surface. ADINA is formulated on waterbased dispersion, flame retardants, refractory fillers and blowing agents.

Application Field

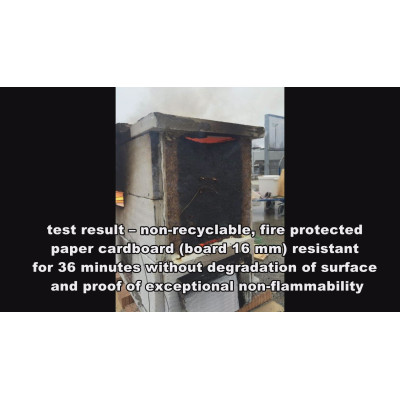

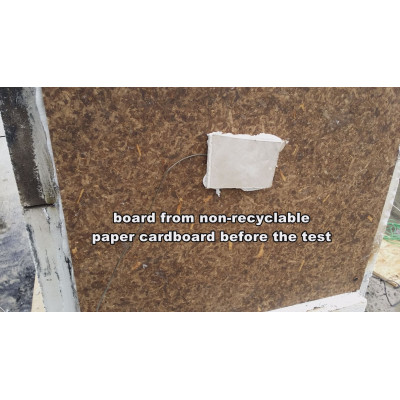

SADINA is designed to protect wood and wood-based products against the effects of fire and radiant heat. Due to its composition, ADINA is suitable for interior and exterior surface fire protective coating on OSB boards that are used for the sandwich system in wood panel houses.

ADINA is characterized by an extraordinary adhesion and abrasion resistance. Wood products treated with ADINA are able to withstand the mechanical stresses, shocks, transporting, cutting, sawing and establishment during installation.

It is necessary to emphasize that ADINA differs from market available technical coatings. By application of ADINA, the surface is visually comparable to decorative coatings.

Functional Features

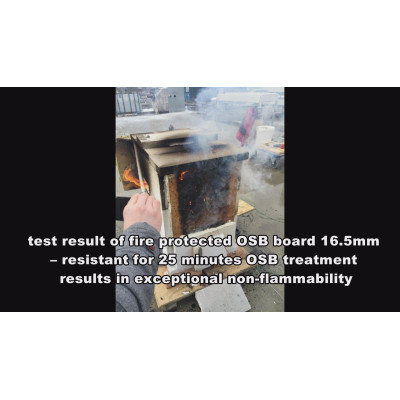

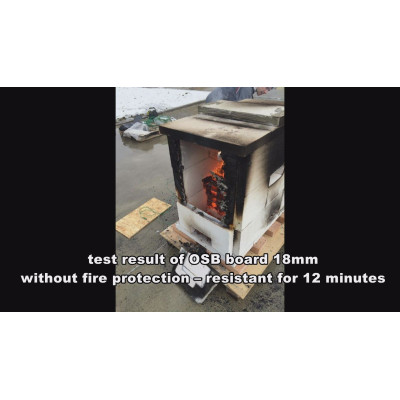

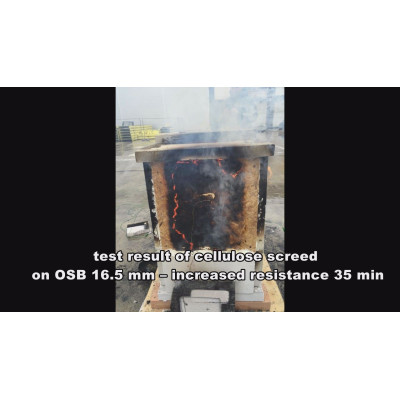

Fire resistant paint "ADINA" creates thick protective, flame retardant and insulating layer on the surface by thermal decomposition while burning process. The layer increases the fire resistance of the wood against exposure to flames and radiant heat.

| Performance Data | CLASSIFICATION form of Reaction to Fire STN EN 13501-1 + A1: 2010 |

| Reaction to Fire Classification | B-s2, d0 for coverage rate 350 g/m2 of ADINA |

| Classification of Fire Resistance | EI 15, EI 30, EI 45. Applies to coverage rate from 350 g/m2 to max. 2000 g/m2 |

Physical and Technical Characteristics

| Dry Content | > 67,1% |

| Solvent Content | VOC / EC / 0% |

| Density | 1,314 g/cm3 |

| pH | 8,3 |

| Adhesion to Substrate | Concrete - 2,27 Mpa |

| Wood - 0,72 Mpa | |

| Abrasion Resistance | 57 seconds grinding |

Application Steps

Surface Preparation

Apply material ADINA to the substrate with relative humidity max.20%, clean off preservatives to achieve perfect adhesion to the substrate.

Preparation of Materials

ADINA material must be mixed thoroughly before application and during the application process must be continuously stirred.

Hand Application

spatula, brush, roller

Dilution with Water

As needed for different type of application.

Air Spray

2.5 mm nozzle, pressure 4 bars.

Drying

For ADINA industrial application the application procedure is developed with recommended drying time.

Applying

Based on ADINA physical property is not advised apply more than 1000 g/m2 in one layer.

Apply in dry conditions at the optimum temperature of about 25 ± 2 °C and relative humidity of 50 ± 5%. Low temperatures and high relative humidity delays drying and can cause a variety defects on applied surface.

Storage

Store in dry conditions at temperatures between +5 and +25 ° C. It must not be exposed to freezing temperatures or direct sunlight.